China Standard Cheap Price Nylon Plastic Steel Motorcycle Chain and Sprocket Gear Manufacturer

Product Description

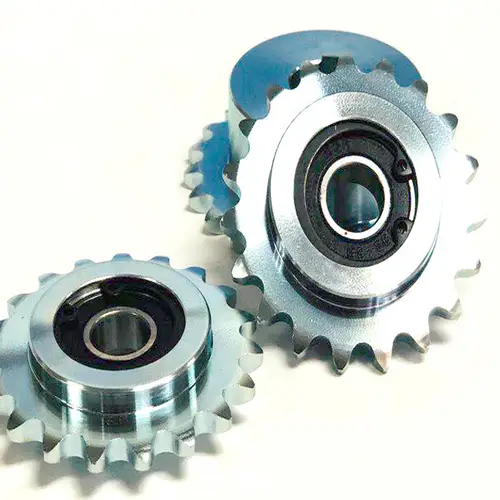

Cheap Price Nylon Plastic Steel Motorcycle Chain and Sprocket Gear

Sprocket

A sprocket is a profiled wheel with teeth that meshes with a chain, track, or other perforated or indented material. It is distinguished from a gear because sprockets are never meshed together directly and differs from a pulley in that sprockets have teeth while pulleys are smooth.

Sprockets Feature as follows:

- Material: C45, Stainless steel 304, A3, etc.

- High precision available as per your request.

- Sprocket processing: Forging, cast iron, Machining (shaping, hobbing, etc.)

- Good quality with the most competitive price.

- Surface treatments such as high-frequency quenching and hardened teeth can be 40-50 HRC.

- Special rubber can be fixed on the teeth bottom to reduce noise and wear.

- Available in standard and non-standard sprockets.

Product Parameters

- Sprocket: All sprockets supplied are suitable for chains made in accordance with standard DIN 8187 or ANSI, from simplex, duplex to triplex.

- Material: Alloy steel, carbon steel, stainless steel, hardened & tempered steel, cast iron, aluminum, copper, brass, and so on.

- Heat treatment: Hardening and tempering, high-frequency quenching, carburizing, and quenching.

- Surface treatment: Galvanizing/zinc plating, dacrotized, black anodic treatment, spray painting, mirror finish, burnishing, sand-blasting.

- Inspection: All items are checked and tested thoroughly during every working procedure to ensure that the best quality products will be sold in the market.

Packaging & Shipping

All products can be packed in cartons, or you can choose pallet packing. "MADE IN CHINA" can be pressed on wooden cases. Land, air, and sea transportation are available. UPS, DHL, TNT, FedEx, and EMS are all supported.

FAQ

1. MOQ

A: Generally, 1 pc for standard parts; contact us for non-standard parts.

2. Delivery Time

A: In stock: within 5 working days. Out of stock: depends on your order quantity.

3. How To Select

A: Provide part number or drawing, or catalogue. If unavailable, send us your sample, and we can create the drawing and sample accordingly.

4. What is the Warranty for your products?

A: Normally our warranty is 1 year.

Other Products

EVER-POWER GROUP mainly supplies various products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. We highlight our high-quality products, preferential prices, and considerate services. Customers are welcome to customize drawings and samples.

FAQs

1. What materials are used for your sprockets?

A: We use alloy steel, carbon steel, stainless steel, hardened & tempered steel, cast iron, aluminum, copper, brass, and more.

2. Can I customize the sprocket specifications?

A: Yes, high precision is available as per your request, and we offer both standard and non-standard sprockets.

3. What surface treatments do you provide?

A: Our surface treatments include galvanizing/zinc plating, dacrotized, black anodic treatment, spray painting, mirror finish, burnishing, and sand-blasting.

4. How do you ensure product quality?

A: All items are thoroughly checked and tested during every working procedure to ensure the best quality products are sold in the market.

5. What is the usual lead time for orders?

A: For in-stock items, within 5 working days. For out-of-stock items, it depends on your order quantity.

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Sprocket Gear

Sprocket gears are pivotal components in various mechanical systems, offering numerous performance characteristics that enhance their functionality and efficiency.

High Precision

The toothed design of sprocket gears ensures precise engagement with chains, providing accurate motion control and reducing slippage.

Durability

Sprocket gears are constructed from robust materials that offer exceptional resistance to wear and tear, extending the lifespan of the gear and the machinery it operates within.

Load Distribution

The design of sprocket gears allows for even distribution of load across the entire gear, minimizing the risk of gear teeth failure and enhancing the stability of the mechanical system.

Types and Characteristics of Sprocket Gears

Sprocket gears come in various types, each designed to meet specific applications and performance requirements.

Roller Chain Sprockets

These are the most common type, used extensively in bicycles, motorcycles, and industrial machinery. They are designed to interface with roller chains, providing smooth and efficient motion transfer.

Silent Chain Sprockets

These sprockets are engineered to work with silent chains, offering quieter operation and reduced vibration in high-speed applications.

Double Pitch Sprockets

Double pitch sprockets are utilized in conveyor systems and are characterized by their extended tooth spacing, which reduces the overall chain speed and wear.

Advantages of Sprocket Gears Made of Different Materials

Material selection plays a critical role in the performance and durability of sprocket gears.

Steel Sprockets

Steel sprockets are known for their strength and durability, making them suitable for heavy-duty applications where high load capacity is required.

Aluminum Sprockets

Aluminum sprockets are lightweight and corrosion-resistant, making them ideal for applications where weight reduction is essential, such as in racing vehicles.

Plastic Sprockets

Plastic sprockets offer excellent resistance to chemicals and moisture, making them suitable for applications in food processing and other wet environments.

Applications of Sprocket Gears in Various Industries

Sprocket gears are indispensable in numerous industries due to their versatile applications and reliability.

Automotive Industry

In the automotive industry, sprocket gears are used in timing systems, ensuring the precise synchronization of engine components for optimal performance.

Industrial Machinery

Sprocket gears are integral to various industrial machines, including conveyors, mixers, and milling machines, providing reliable motion transfer and reducing downtime.

Agricultural Equipment

In agricultural machinery, such as tractors and harvesters, sprocket gears facilitate the efficient transfer of power, improving productivity and reducing operational costs.

Construction Equipment

Sprocket gears in construction equipment, like excavators and cranes, ensure smooth operation and enhance the safety and efficiency of these machines.

Marine Applications

Marine vessels use sprocket gears in various systems, including anchor handling and propulsion systems, providing reliable operation in harsh marine environments.

Future Development Trends and Opportunities of Sprocket Gear Products

The sprocket gear industry is continuously evolving, with several trends and opportunities shaping its future.

Advanced Materials

The development of new materials, such as composites and advanced alloys, is expected to enhance the performance and durability of sprocket gears.

Smart Gears

Integration of sensors and IoT technology in sprocket gears will enable real-time monitoring of gear performance and predictive maintenance, reducing downtime and extending gear life.

3D Printing

3D printing technology offers the potential for rapid prototyping and customization of sprocket gears, reducing lead times and manufacturing costs.

How to Choose a Suitable Sprocket Gear

Selecting the right sprocket gear involves several critical considerations to ensure optimal performance and longevity.

Clear Requirements

Identify the specific requirements of your application, including load capacity, speed, and environmental conditions.

Material Selection

Choose the appropriate material based on the application's demands, considering factors such as strength, weight, and corrosion resistance.

Design Optimization

Optimize the design of the sprocket gear to ensure efficient load distribution and reduce wear.

Suppliers and After-Sales Service

Select a reputable supplier that offers comprehensive after-sales support, including maintenance and replacement services.

Cost-Effectiveness

Evaluate the cost-effectiveness of the sprocket gear, balancing initial investment with long-term operational costs.

Quality Control

Ensure the sprocket gear meets stringent quality control standards to guarantee reliable performance and longevity.

Conclusion

Sprocket gears are essential components in various mechanical systems, offering precision, durability, and versatility. By understanding their performance characteristics, types, material advantages, and applications, you can make an informed decision when selecting the right sprocket gear for your needs. Additionally, staying abreast of future development trends and considering key factors such as material selection, design optimization, and supplier reliability will help ensure the optimal performance and longevity of your sprocket gears.

Author: Dream