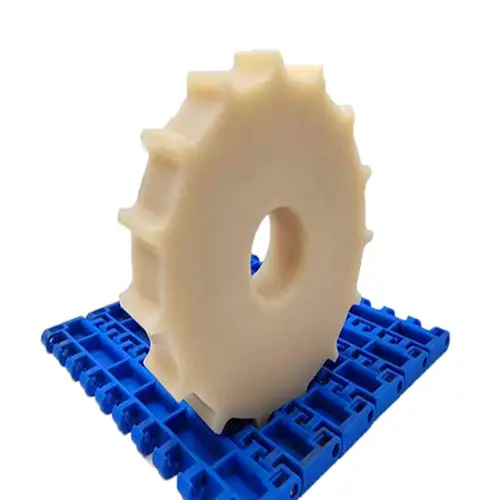

Top-Quality Self Lubricating Transmission Nylon Sprocket Compression Gear for Agricultural Machinery

Product Description

Welcome to our top-tier, self-lubricating transmission nylon sprocket compression gear, meticulously designed for agricultural machinery. Our product is crafted to provide unparalleled performance and durability, ensuring prolonged efficiency in diverse agricultural applications.

Plastic Part Products Characteristic

- Well Shape Keeping

- Deburr, Sharp Edge and Flash

- Precision Tolerance Control

- Nice Surface Treatment

- Colorful Choice

Product Specifications

| Material | ABS, ASA, PP, PA, PC, PE, POM, HDPE, TPE, TPU, PVC, PBT etc. |

| Material Report | FDA, ROHS, UL, WRAS and REACH |

| Dimension | Standard Sizes or As per customers' Requirement |

| Certifications | ISO9001, IATF16949, ISO14001 |

| Color | Any colors according to PANTONE or RAL |

| Surface Finish | Texture (VDI/MT standard, or made to client's sample), polished (high polish, mirror polish), smooth, painting, powder coating, printing, electroplating etc. |

| Service | Custom Made or OEM and ODM |

| Free Samples | Okay |

| Production Ways | CAD Drawing, 3D Files or Samples |

| Production Capacity | 200T, 300T and 500T Compressing Molding, Injection Molding, Auto Vacuum Vulcanizing, Plastic Injection, and Extrusion |

| Supplying Capacity | One Million Pieces/ Month |

| Tolerance | Generally ±0.05mm or Better |

| QC | PPAP, In House Control, Third Party Inspection Institution such SGS, TUV |

| Lead Time | 15 Days for Molding, 15-20 Days for Series Production |

| Application | Industry Machinery, Automotive, Mechanical Equipment, Construction, House Application, Medical Machine |

| More Parts |

Grommet, sleeve, feet, gasket, wheel, bellow, cap, dust cover, pad, washer, strip, plug, stopper, grip, seal, bushing, bumper, blocks, and anti-vibration mounts etc. |

Our Other Product Lines

EVER-POWER GROUP is dedicated to delivering high-caliber industrial components including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, and bushings. We offer bespoke solutions tailored to your needs at competitive prices, accompanied by exceptional service. Customers are encouraged to submit custom drawings and samples for their unique requirements.

Frequently Asked Questions (FAQs)

1. What types of plastic materials do you use?

We use a broad array of plastics, including ABS, ASA, PP, PA, PC, PE, POM, HDPE, TPE, TPU, PVC, PBT, and more.

2. Can you provide customization services?

Yes, we offer custom made, OEM, and ODM services. We can work with CAD drawings, 3D files, or physical samples to meet your specific needs.

3. What is your typical lead time?

Our standard lead time is 15 days for molding and 15-20 days for series production.

4. Are free samples available?

Yes, we provide free samples to help you evaluate the quality and compatibility of our products.

5. What quality control measures do you have in place?

Our quality control process includes raw material inspection, mold inspection, product inspection during production, and finished product inspection to ensure 100% qualification in appearance and size.

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Sprocket Gear

Sprocket gears are pivotal components in various mechanical systems, offering numerous performance characteristics that enhance their functionality and efficiency.

High Precision

The toothed design of sprocket gears ensures precise engagement with chains, providing accurate motion control and reducing slippage.

Durability

Sprocket gears are constructed from robust materials that offer exceptional resistance to wear and tear, extending the lifespan of the gear and the machinery it operates within.

Load Distribution

The design of sprocket gears allows for even distribution of load across the entire gear, minimizing the risk of gear teeth failure and enhancing the stability of the mechanical system.

Types and Characteristics of Sprocket Gears

Sprocket gears come in various types, each designed to meet specific applications and performance requirements.

Roller Chain Sprockets

These are the most common type, used extensively in bicycles, motorcycles, and industrial machinery. They are designed to interface with roller chains, providing smooth and efficient motion transfer.

Silent Chain Sprockets

These sprockets are engineered to work with silent chains, offering quieter operation and reduced vibration in high-speed applications.

Double Pitch Sprockets

Double pitch sprockets are utilized in conveyor systems and are characterized by their extended tooth spacing, which reduces the overall chain speed and wear.

Advantages of Sprocket Gears Made of Different Materials

Material selection plays a critical role in the performance and durability of sprocket gears.

Steel Sprockets

Steel sprockets are known for their strength and durability, making them suitable for heavy-duty applications where high load capacity is required.

Aluminum Sprockets

Aluminum sprockets are lightweight and corrosion-resistant, making them ideal for applications where weight reduction is essential, such as in racing vehicles.

Plastic Sprockets

Plastic sprockets offer excellent resistance to chemicals and moisture, making them suitable for applications in food processing and other wet environments.

Applications of Sprocket Gears in Various Industries

Sprocket gears are indispensable in numerous industries due to their versatile applications and reliability.

Automotive Industry

In the automotive industry, sprocket gears are used in timing systems, ensuring the precise synchronization of engine components for optimal performance.

Industrial Machinery

Sprocket gears are integral to various industrial machines, including conveyors, mixers, and milling machines, providing reliable motion transfer and reducing downtime.

Agricultural Equipment

In agricultural machinery, such as tractors and harvesters, sprocket gears facilitate the efficient transfer of power, improving productivity and reducing operational costs.

Construction Equipment

Sprocket gears in construction equipment, like excavators and cranes, ensure smooth operation and enhance the safety and efficiency of these machines.

Marine Applications

Marine vessels use sprocket gears in various systems, including anchor handling and propulsion systems, providing reliable operation in harsh marine environments.

Future Development Trends and Opportunities of Sprocket Gear Products

The sprocket gear industry is continuously evolving, with several trends and opportunities shaping its future.

Advanced Materials

The development of new materials, such as composites and advanced alloys, is expected to enhance the performance and durability of sprocket gears.

Smart Gears

Integration of sensors and IoT technology in sprocket gears will enable real-time monitoring of gear performance and predictive maintenance, reducing downtime and extending gear life.

3D Printing

3D printing technology offers the potential for rapid prototyping and customization of sprocket gears, reducing lead times and manufacturing costs.

How to Choose a Suitable Sprocket Gear

Selecting the right sprocket gear involves several critical considerations to ensure optimal performance and longevity.

Clear Requirements

Identify the specific requirements of your application, including load capacity, speed, and environmental conditions.

Material Selection

Choose the appropriate material based on the application's demands, considering factors such as strength, weight, and corrosion resistance.

Design Optimization

Optimize the design of the sprocket gear to ensure efficient load distribution and reduce wear.

Suppliers and After-Sales Service

Select a reputable supplier that offers comprehensive after-sales support, including maintenance and replacement services.

Cost-Effectiveness

Evaluate the cost-effectiveness of the sprocket gear, balancing initial investment with long-term operational costs.

Quality Control

Ensure the sprocket gear meets stringent quality control standards to guarantee reliable performance and longevity.

Conclusion

Sprocket gears are essential components in various mechanical systems, offering precision, durability, and versatility. By understanding their performance characteristics, types, material advantages, and applications, you can make an informed decision when selecting the right sprocket gear for your needs. Additionally, staying abreast of future development trends and considering key factors such as material selection, design optimization, and supplier reliability will help ensure the optimal performance and longevity of your sprocket gears.

Author: Dream